At Altiras Labs, we specialize in solving complex emulsion challenges through a combination of cutting-edge chemical and physical processes. Our Emulsion Breaking Research Studies evaluate and optimize the most effective methods for breaking down emulsions. This allows you to achieve cleaner separation and maximize value from your streams. With a thorough approach to both chemical and physical methods, our emulsion-breaking study delivers solutions that enhance process efficiency and product quality.

What is an Emulsion?

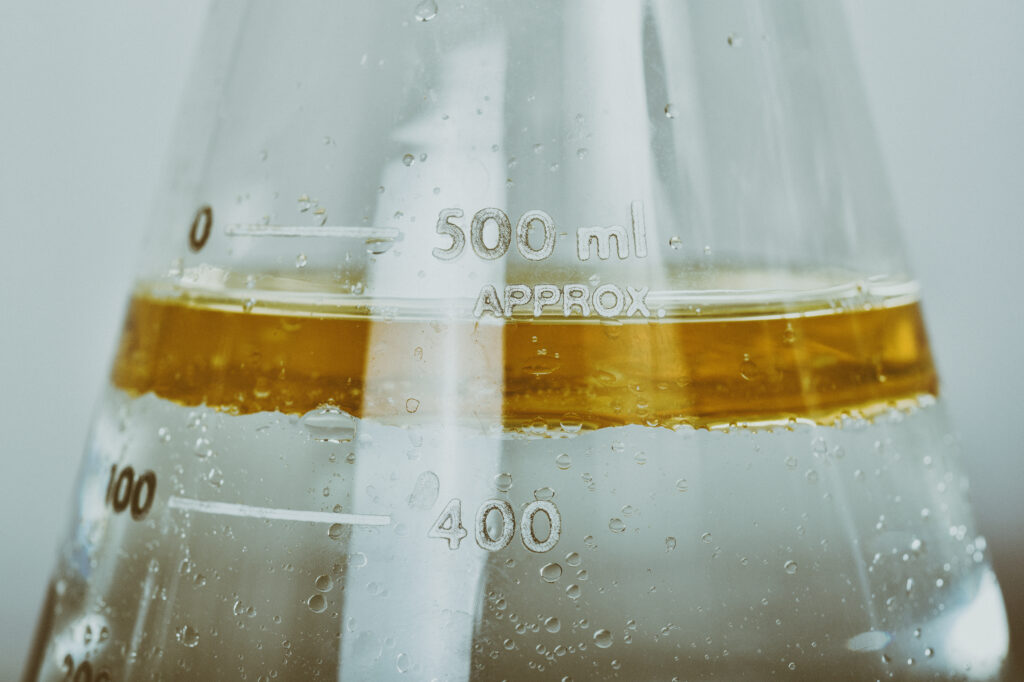

An emulsion is a mixture of two immiscible liquids, typically consisting of oil and water, where one liquid is dispersed in the other in the form of small droplets. Emulsions are commonly found in many industries, including the chemical, petrochemical, oil and gas, and wastewater treatment sectors. While emulsions can be useful in some applications, they often present significant challenges when separation is required. Effective emulsion breaking is essential to separating these liquids, allowing for efficient processing, recovery of valuable components, and reduction of waste.

The Importance of Emulsion-Breaking Research in the Chemical and Petrochemical Industries

Emulsions can hinder processing, lower product quality, and raise operational costs. These emulsions form during processes like oil extraction and wastewater treatment. Surfactants and impurities can stabilize them, making them hard to break. Stabilized emulsions lead to inefficiencies, such as higher energy use and equipment fouling.

Breaking emulsions effectively is key to overcoming these challenges. By implementing the findings of emulsion-breaking studies, companies can recover valuable components from the emulsion, minimize waste, and improve the overall efficiency of their operations. For example, in oil recovery, breaking water-in-oil emulsions reduces water content, cutting dehydration costs. In wastewater treatment, breaking oil-in-water emulsions removes contaminants and meets environmental standards.

At Altiras Labs, our emulsion breaking study identifies the ideal chemical emulsion breakers. We determine the precise concentrations and conditions for optimal performance. Each emulsion is unique, so we develop customized solutions for your operation. Our expertise ensures we select the best formulations and strategies to break even the toughest emulsions. This improves process efficiency and product quality.

Combining Chemical and Physical Solutions for Emulsion Breaking

Breaking emulsions effectively often requires a combination of chemical and physical methods. At Altiras Labs, our emulsion-breaking research studies go beyond evaluating chemical emulsion breakers alone. We also assess the best physical and process methods for breaking emulsions, such as agitation, temperature adjustments, or other mechanical interventions. By integrating both chemical and physical approaches, we provide comprehensive solutions that deliver the most efficient and cost-effective result.

Chemical emulsion breakers, also known as demulsifiers, are substances that help destabilize and separate the dispersed droplets in an emulsion. These chemicals reduce the interfacial tension between the oil and water phases, allowing the droplets to coalesce and separate more easily. Our emulsion-breaking study carefully evaluates different demulsifiers to determine which chemical formulations are most effective for a particular emulsion. Factors such as the type of emulsion, temperature, pH, and emulsion stability are all considered when selecting the ideal chemical breaker.

In addition to chemical solutions, our study evaluates physical methods for breaking emulsions. Physical approaches, such as heating, can reduce the viscosity of the emulsion and enhance the effectiveness of chemical demulsifiers. Mechanical methods, such as centrifugation, can also be employed to accelerate the separation process. By combining these physical interventions with optimized chemical treatments, we can achieve effective emulsion-breaking with minimal energy input and cost.

Applications of Emulsion Breaking in the Chemical and Petrochemical Industries

The insights gained from an emulsion-breaking study have a wide range of applications in the chemical and petrochemical industries. In the oil and gas sector, emulsions often form during crude oil extraction and processing. This leads to challenges in separating oil from water and other impurities. Effective emulsion breaking is essential for improving the quality of crude oil and reducing the cost of downstream processing. Our emulsion-breaking study provides tailored solutions for these challenges, ensuring that oil producers can efficiently separate and recover valuable resources.

In chemical processing, emulsions can form during reactions, blending, or as byproducts of various processes. These emulsions can lead to fouling of equipment, reduced product quality, and increased waste. By conducting an emulsion-breaking study, we help chemical manufacturers identify the best methods for separating emulsions and optimizing their processes. This not only improves product quality but also reduces waste and operational costs.

In wastewater treatment, emulsions containing oil or other hydrophobic substances can be difficult to treat and can prevent facilities from meeting environmental regulations. Our study offers solutions for breaking oil-in-water emulsions, allowing for the removal of contaminants and compliance with environmental standards.

Partner with Altiras Labs for Emulsion Breaking Research

Whether you are dealing with emulsions in wastewater treatment, oil recovery, or chemical processing, Altiras Labs’ emulsion-breaking study can provide the solutions you need. We work to streamline operations, reduce waste, and recover valuable components. Our expertise and comprehensive approach to chemical solutions ensure you receive the best outcomes for your industry challenges.

Contact us today to learn more about how our emulsion-breaking study can help you achieve your goals.