As companies pursue beneficial reuse strategies to reduce costs and manage materials sustainably, navigating the regulatory environment becomes essential. In this post, we’ll explore the key chemical reuse regulations that manufacturers must follow—and offer best practices for ensuring compliance while still driving economic and environmental value.

What Are Chemical Reuse Regulations?

Beneficial reuse is encouraged by both federal and state agencies, but only under specific conditions. The U.S. Environmental Protection Agency (EPA) outlines criteria to ensure that reuse is legitimate and protective of human health and the environment.

According to the EPA’s reducing and reusing basics, reused materials must:

- Serve a useful purpose in the receiving process

- Be a substitute for a product or material that would otherwise need to be purchased

- Not pose a significant risk of contamination or misuse

If these conditions are met, many reused materials may avoid classification as hazardous waste.

Key Compliance Considerations for Beneficial Reuse

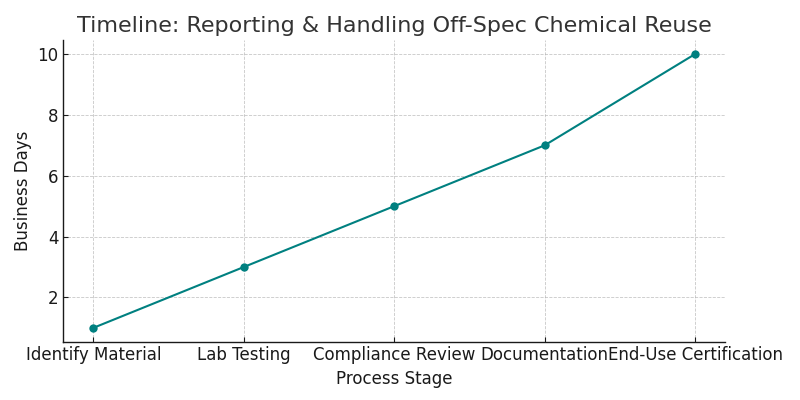

- Legitimate Use Verification

The material must be usable “as is” or with minimal treatment. Using reused materials simply to avoid disposal does not meet legal requirements. - Regulatory Classification

Is the material a co-product, byproduct, or waste? This determines how it must be managed. Reclaimed chemicals, if reused properly, may not require full hazardous waste tracking. - Documentation

Records should clearly show the material’s characteristics, the reuse method, and its equivalence to commercial substitutes. Auditable documentation is critical in regulatory inspections. - End User Certification

If the material is being sold or transferred, both the supplier and receiver should certify that the use complies with applicable regulations and safety standards. - Labeling and Storage

All reuse materials should be clearly labeled and stored according to chemical safety guidelines.

EPA Guidelines by Category

| Chemical Type | Reuse Potential | Regulatory Notes |

| Solvents | High | Must meet purity thresholds for substitution |

| Acids/Bases | Moderate to High | Confirm pH neutrality and corrosion limits |

| Fuels | High | Requires flash point and combustion analysis |

| Aqueous Streams | Variable | May require filtration or pH adjustment first |

For more technical evaluations, Altiras provides standardized testing services to determine whether a stream meets specifications for legal reuse.

Avoiding Common Compliance Pitfalls

- Mislabeling co-products as non-waste without proper documentation

- Failing to document end-user applications

- Neglecting to re-test materials stored for long periods

- Overlooking state-specific rules, which may be more restrictive than federal regulations

Altiras helps companies navigate these challenges through consulting, lab support, and reuse strategy design. Learn more about our chemical reuse compliance services.

Infographic Idea: Compliance Checklist for Beneficial Reuse

- Confirm beneficial purpose

- Analyze chemical composition

- Certify end use

- Maintain documentation

- Label and store correctly

Conclusion

Chemical reuse regulations don’t have to be a barrier. In fact, they create a framework for safely turning waste into opportunity. By following EPA guidance, partnering with experienced reuse firms, and investing in documentation, chemical companies can unlock new value streams—without increasing compliance risk.As we continue to face the pressures of cost, supply chain instability, and regulation, mastering the chemical reuse regulations will be key to long-term operational and environmental success.