Sustainable Chemical Processes That Improve Performance and Cut Waste

Sustainability is not merely a marketing trend but an operational necessity. In today’s regulatory and competitive environment, chemical and petrochemical plants face significant pressure to minimize waste, lower energy consumption, and achieve ESG targets. Plant managers aren’t deciding whether to adopt sustainability, but rather how to do so without sacrificing productivity or profitability. Altiras Labs helps companies solve this challenge by implementing sustainable chemical processes. Through targeted lab-scale research, we improve operational efficiency, enhance waste recovery, and reduce overall energy consumption, turning sustainability into measurable business advantages.

The Environmental and Financial Impact of Inefficient Operations

Traditional chemical processes often produce excess waste and emissions, negatively affecting both environmental performance and the bottom line. Key inefficiencies include excessive waste generation, often due to limited recovery or separation capabilities. Energy-intensive operations further compound these challenges, increasing costs and emissions. Additionally, valuable byproducts frequently go unrecovered, representing lost economic opportunities. Altiras Labs addresses these challenges directly by developing sustainable chemical processes tailored to your plant’s needs.

How Altiras Labs Supports Sustainable Chemical Processes

Altiras Labs partners with clients to develop sustainable chemical processes through rigorous lab-based studies. Our research services include:

- Distillation Studies: Enhance separation techniques for complex mixtures and azeotropes to reclaim valuable products and reduce waste disposal.

- Adsorption Studies: Evaluate resins and activated carbon systems to efficiently remove contaminants or recover valuable solvents.

- Emulsion-Breaking Studies: Optimize methods for separating oil-water mixtures to reclaim fuels and reduce water contamination.

- Centrifuge Studies: Improve solids-liquid separation efficiency to boost throughput and minimize environmental load.

- Membrane Filtration Studies: Apply advanced membrane technologies such as nanofiltration and reverse osmosis to maximize chemical recovery and minimize waste.

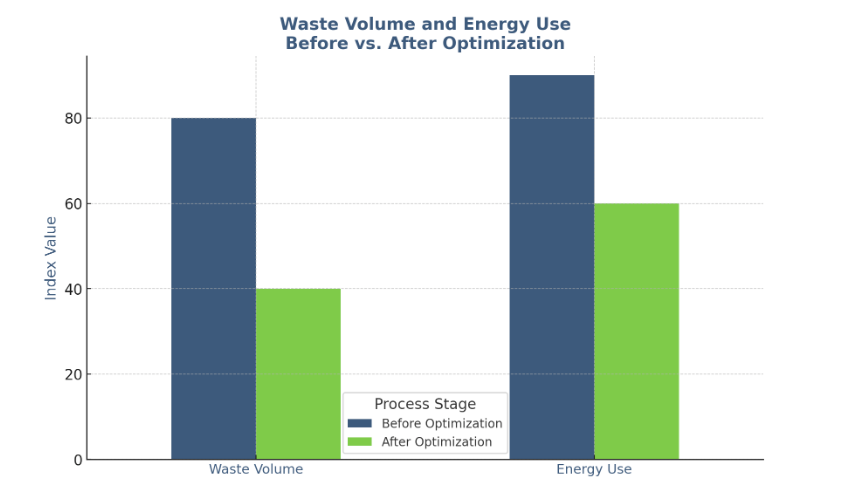

Key Benefits of Sustainable Chemical Processes

Implementing sustainable chemical processes through Altiras Labs delivers measurable outcomes, including:

- Chemical Recycling & Beneficial Reuse: Transform waste streams into valuable feedstocks or marketable products.

- Energy Reduction: Optimize processes to lower energy demands, reduce operational costs, and shrink carbon footprints.

- Waste Minimization: Significantly reduce waste generation, disposal costs, and environmental impact through strategic process improvements.

Let’s Build a More Sustainable Operation—Together

At Altiras Labs, sustainable chemical processes aren’t just good for the environment—they’re great for your business. Whether you’re focused on cutting costs, reducing waste, or meeting ambitious ESG goals, our expert-driven solutions deliver real results. Contact us today to start your sustainability journey and turn your environmental challenges into competitive advantages.