As global trade conditions shift under the weight of new tariffs, the U.S. chemical industry must respond with smart, resilient strategies. In this week’s article, we explore how companies can redesign their chemical supply chain strategies to weather the impacts of rising costs, global uncertainty, and material shortages.

How Tariffs Disrupt Chemical Supply Chains

The 2025 tariff announcements added duties of up to 25% on thousands of imported goods—including base chemicals and specialty ingredients. These changes immediately altered sourcing economics and introduced new risks into chemical supply planning.

Reuters reports that companies like Edgewell Personal Care are proactively negotiating long-term contracts to secure materials ahead of further tariff increases.

Strategic Chemical Supply Chain Responses

Here are four proven strategies for creating a tariff-resilient chemical supply chain:

- Source Locally

Domestic production avoids tariffs and shipping delays. While some raw materials are still limited, alternatives are growing, including beneficial reuse and reprocessed co-products. - Diversify Suppliers

Over-reliance on one region is risky. Companies should vet suppliers from non-tariffed regions and invest in dual sourcing. - Use Reclaimed or Off-Spec Inputs

Many off-spec or surplus chemicals meet functional specs and are available without import costs. Altiras’ beneficial reuse program is designed to help. - Secure Inventory Through Long-Term Agreements

By locking in multi-year contracts or volume-based pricing, companies can stabilize costs even during market volatility.

Infographic: Strategic Response Options

- Diversify vendor base

- Reshore sourcing

- Use co-product materials

- Invest in reuse/reformulation

Internal Logistics Optimization

A robust chemical supply chain strategy also includes logistical planning:

- Inventory Buffering: Maintain higher safety stock for tariff-sensitive items.

- Shorter Distribution Routes: Reduce lead time by working with regional hubs.

- Blending & Reformulation: Use available inputs in new combinations to replace harder-to-source imports.

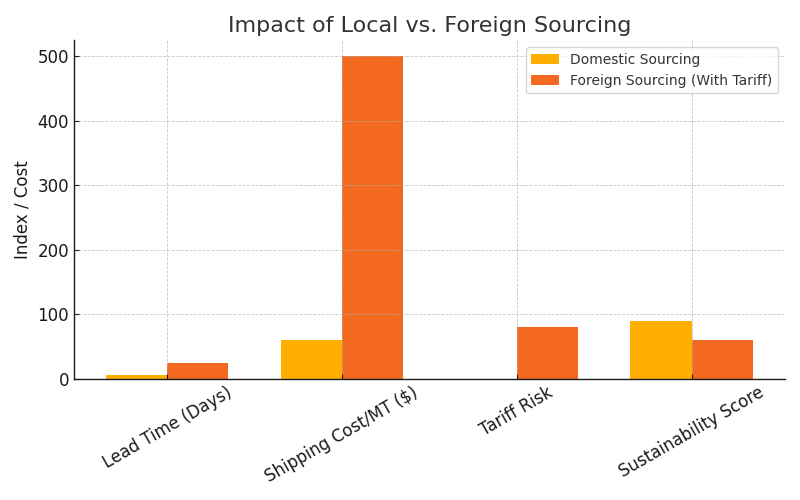

Chart: Local vs. Foreign Sourcing Impact on Lead Time & Cost

| Metric | Domestic Sourcing | Foreign Sourcing (with Tariff) |

| Average Lead Time | 3–5 days | 14–30 days |

| Shipping Cost/MT | $60 | $300–$800 |

| Tariff Risk | None | High |

| Sustainability Score | High | Medium |

Conclusion

There’s no denying that tariffs pose challenges—but they also spark innovation. Companies that adopt forward-looking chemical supply chain strategies can not only reduce risk but also unlock new efficiencies, supplier relationships, and circular solutions.

From sourcing alternatives to localizing distribution, Altiras supports manufacturers with the tools and partners they need to adapt. Explore how our reuse solutions and testing lab can strengthen your supply chain from the inside out.

Stay tuned next week as we explore the long-term benefits of building a sustainable and resilient U.S. chemical manufacturing industry.