In today’s industrial landscape, residual streams like off-spec chemicals and co-products are often written off as waste. But what if they’re not waste at all? What if they’re hidden resource streams—untapped sources of revenue and sustainability gains? What if commercialization research for chemical byproducts could allow you to reclaim value from this supposed waste?

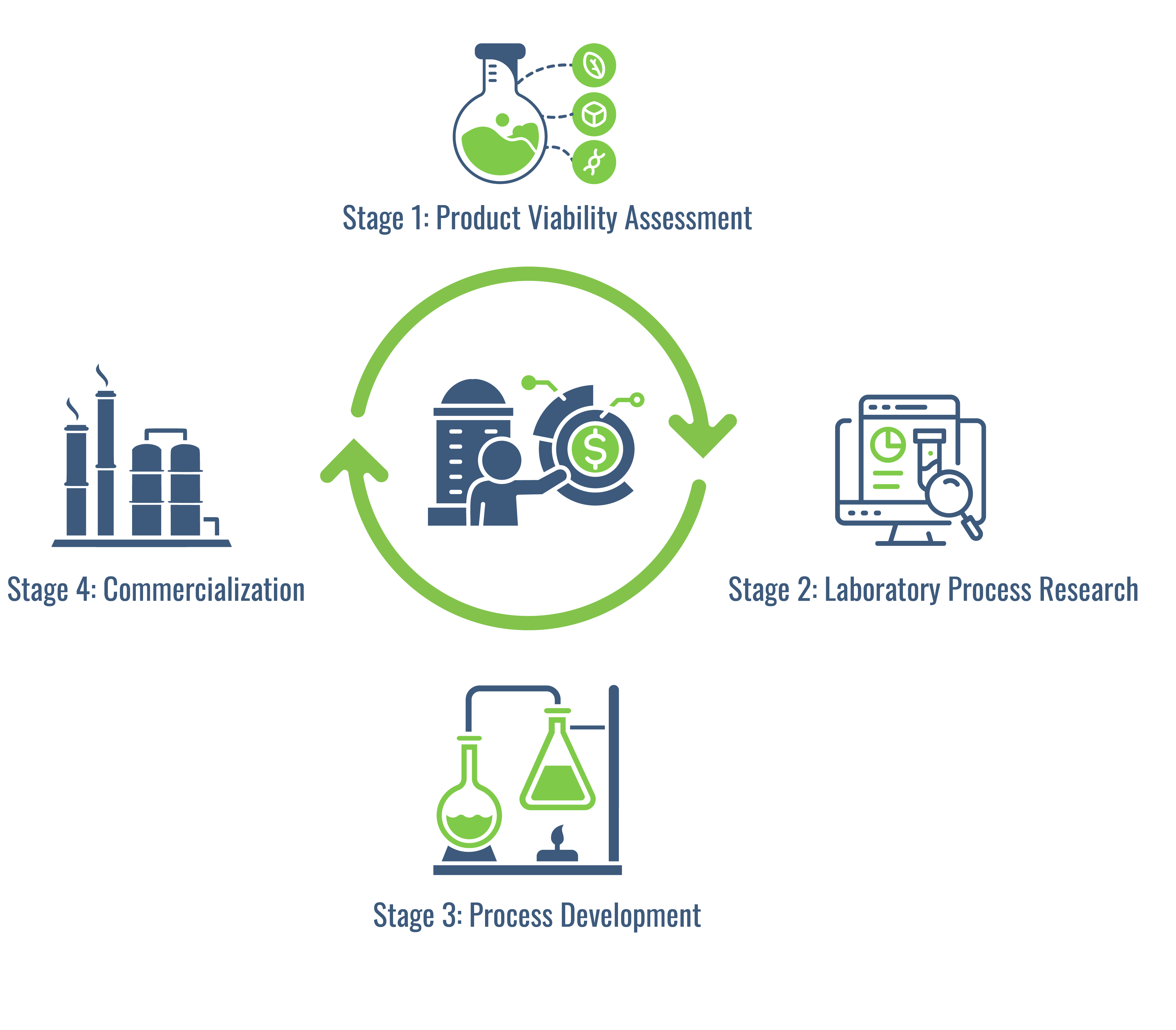

At Altiras, we help companies realize this potential through a structured, scalable approach. Our 4-stage commercialization research process is for industries that generate chemical and fuel byproducts. Whether you’re a plant manager trying to lower disposal costs or an EHS director pursuing sustainability goals, our process is designed to move your material from idle to income.

Stage 1: Product Viability Assessment

Before diving into lab work or process development, we start by determining if your material has true potential for commercialization. Our team evaluates chemical composition, material history, packaging, volume, and potential market uses.

This stage is key for:

- Surplus chemical blends with no clear end-use

- Fuel tank bottoms and contaminated loads

- Co-products from distillation or manufacturing

We use this assessment to identify whether your material is recoverable, blendable, or reusable—and how it fits into market demand.

Stage 2: Laboratory Process Research

Once viability is established, we move into the lab. Altiras Labs performs targeted testing to determine separation, purification, or recovery potential. Whether you need distillation, membrane separation, or emulsion breaking, we tailor the research to the material type and end-use goals.

Our in-house testing helps reduce guesswork, accelerate timelines, and ensure compliance with downstream specs or regulations.

Stage 3: Process Development

Next, we develop a scalable process for preparing your material for reuse or resale. This includes bench-scale trials, process mapping, and pilot-scale evaluations when needed.

Altiras Fuels and Altiras Chemicals help match recovered materials with real-world specs and distribution requirements. This integration ensures your material isn’t just technically recoverable—it’s market-ready.

Stage 4: Capital Project Development

For high-potential materials, we support full commercialization—designing, building, or optimizing systems for long-term material recovery. In many cases, Altiras partners with the client or acts as the off-taker, ensuring a consistent home for the recovered stream.

Examples include:

- Co-product fuel blending programs

- On-site recovery of expired or off-spec solvents

- Infrastructure upgrades for large-volume reuse

Why Altiras for Commercialization Research for By-Products?

Altiras brings together laboratory precision and industrial execution. Our unique model integrates:

- Altiras Labs for lab-scale innovation and validation

- Altiras Fuels for recovered fuel logistics and blending

- Altiras Chemicals for chemical reuse, sales, and compliance support

With all three divisions aligned, we deliver faster turnarounds, regulatory insight, and real supply chain value.

Ready to Unlock Your Hidden Resource Streams?

Stop paying for waste disposal and start looking at what your material could become. Whether you’re managing chemical residuals or off-spec fuels, Altiras can help you unlock the value hiding in your process.

Contact us today to start your commercialization research project.