Many chemical and petrochemical facilities face rising costs, tightening regulations, and increasing pressure to improve environmental performance. Inefficient processes, excessive waste disposal fees, and the underutilization of valuable byproducts are common challenges. That’s why chemical process optimization through targeted research is essential.

Chemical process optimization unlocks innovative strategies to help plant managers improve operational efficiency, reduce waste, and maximize profitability. Whether you’re tackling difficult separations, addressing off-spec product streams, or seeking opportunities for byproduct recovery, process research delivers both economic and environmental value.

Why Chemical Process Research Matters for Your Plant

Chemical process research isn’t just a compliance tool—it’s a strategic investment in your facility’s performance. Below are key reasons why leading petrochemical and chemical plants prioritize chemical process optimization:

Cost Savings Through Process Optimization

By identifying inefficiencies in your process streams, research can uncover ways to:

- Recover and reuse valuable chemicals.

- Minimize raw material waste.

- Reduce off-spec product volumes.

Enhanced Regulatory Compliance

With stricter EPA and state-level regulations, staying compliant is more critical than ever. Chemical process optimization streamlines your facility by:

- Reducing hazardous waste generation.

- Improving emissions profiles.

- Supporting permitting efforts with validated lab data.

Sustainability and Waste Reduction

Process research enables beneficial reuse of byproducts and waste streams through:

- Chemical recycling.

- Advanced separation technologies (membranes, adsorption, distillation).

- Emulsion breaking and water-organic separations.

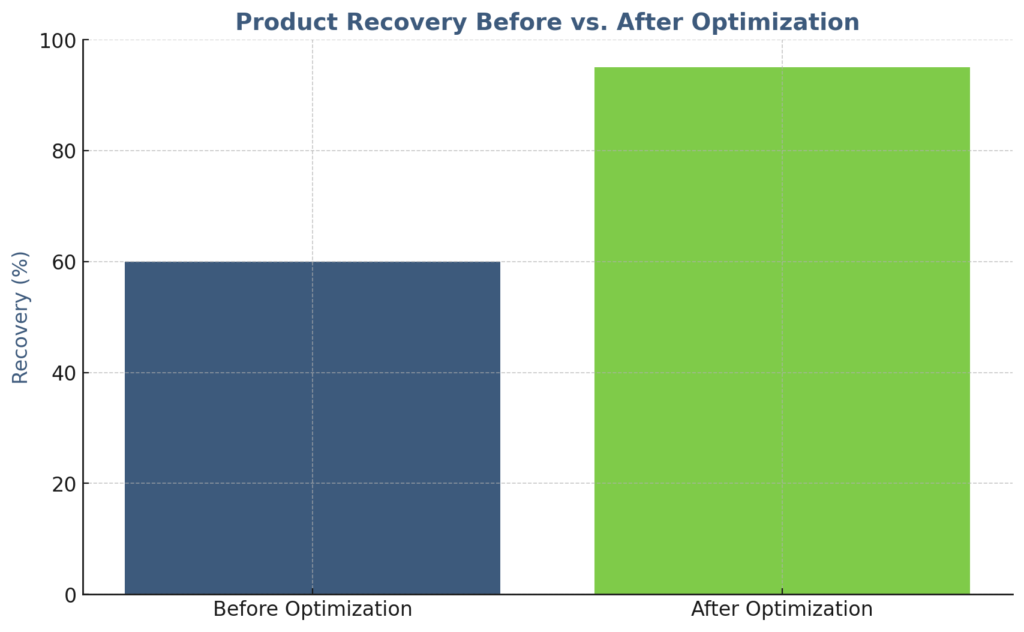

Increased Operational Efficiency

Small changes in process parameters can lead to significant improvements in:

- Throughput and yield.

- Energy consumption.

- Equipment performance and lifecycle.

An example is shown in the graph to the right. Results may vary.

How Altiras Labs Supports Your Plant’s Goals

At Altiras Labs, we partner with plant managers to turn process challenges into performance improvements. Our chemical process research services include:

- Distillation Studies – for separation of complex mixtures or azeotropes.

- Adsorption & Desorption Studies – for targeted removal of impurities or valuable component recovery.

- Emulsion-Breaking Studies – to recover oils or organics from water-based mixtures.

- Centrifuge & Filtration Studies – to optimize solids separation and reduce bottlenecks.

Each study is customized to your feedstock, plant conditions, and business objectives.

Tailored Solutions for Real-World Problems

We don’t just deliver lab reports—we provide actionable strategies that align with your plant’s operational and sustainability goals. Whether you’re exploring ways to:

- Reduce high disposal costs

- Improve your ESG metrics

- Recover valuable byproducts

- Troubleshoot off-spec streams

Altiras Labs delivers data-driven insights and practical recommendations to help you implement chemical process optimization where it matters most.