Membrane Technology

Altiras Labs is leading membrane research in the application of various membrane technologies to real-world chemical recycling needs. We’ve expanded our capabilities to include various membrane technologies, enhancing our portfolio of separation and purification solutions. This move not only underscores our dedication to addressing industrial challenges but also cements our position in the field of chemical process research and development.

ADVANCED SEPARATION SOLUTIONS

Altiras Labs works with ceramic and polymeric composite membranes in various processes including reverse osmosis, nano-filtration, ultra-filtration, micro-filtration, pervaporation, membrane distillation, and more. We perform testing on small flat-sheet units up to larger scale testing that can range from permeate rates of 50 ml/hr to 1900 L/hr. We can test utilizing almost any commercially available membrane and can also custom treat membranes and membrane surfaces to meet our clients’ needs.

EXAMPLE APPLICATIONS OF MEMBRANE TECHNOLOGY

The Altiras Labs team is actively developing processes for challenging separation processes including:

Azeotrope Breaking

Methanol Recovery From Mixed Solvents

Selective Separation Of Multiple Organic Species

Spent Caustic Purification For Reuse

Spent Acid Purification For Reuse

Selective Metals Removal

PFAS Removal

Wastewater Reduction

Altiras Labs has invested heavily in membrane equipment and technology to provide timely and effective testing of membranes in different operating environments. We currently have the following Test Equipment.

EQUIPMENT AND TEST CAPABILITIES

Altiras Labs has invested heavily in membrane equipment and technology to provide timely and effective testing of membranes in different operating environments. We currently have the following Test Equipment.

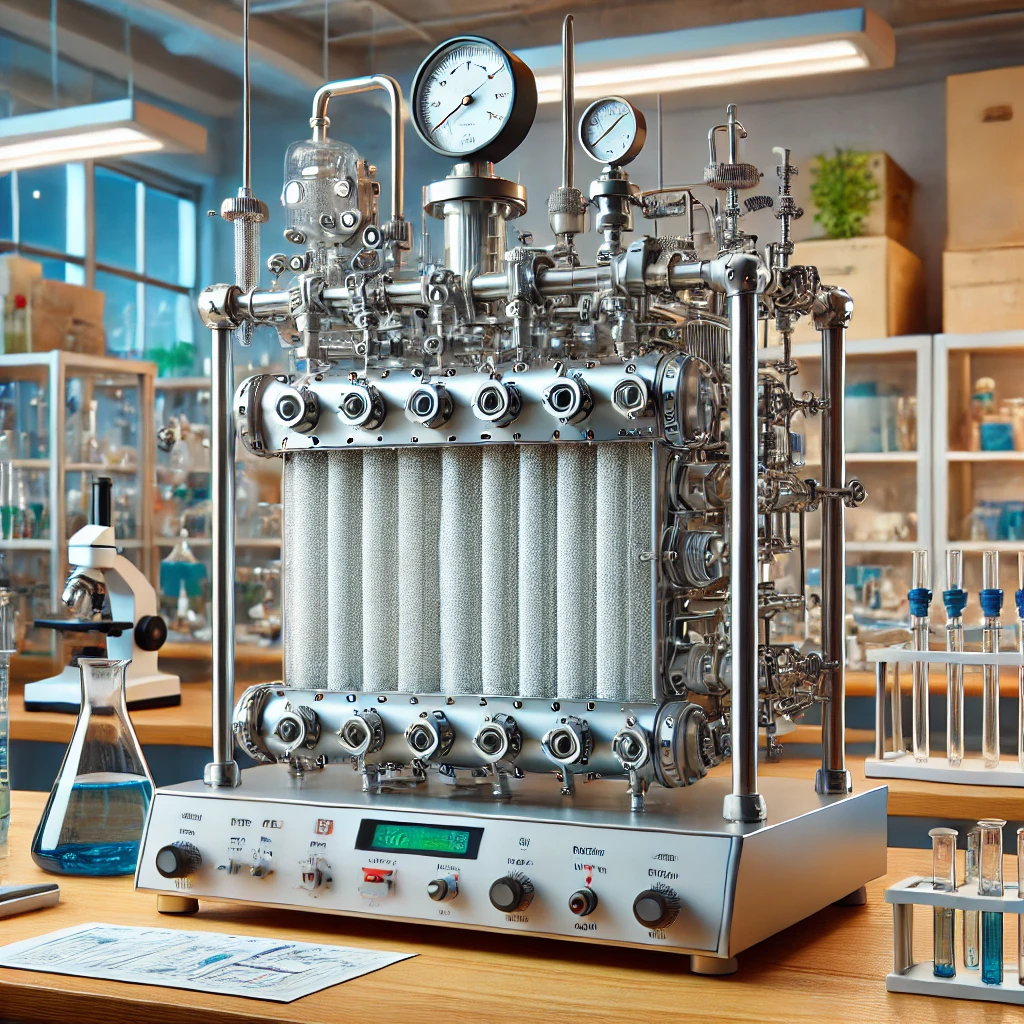

Lab Scale Flat Sheet (High-Pressure Unit)

Designed for low or high-pressure applications, this stainless steel unit supports initial testing in small-scale studies with a surface area of about 266 square centimeters. It tests up to 50 bar (725 psi) and offers a Hastelloy C276 option for strong acids. Primarily, it screens reverse osmosis, nanofiltration, and ultra-filtration membranes.

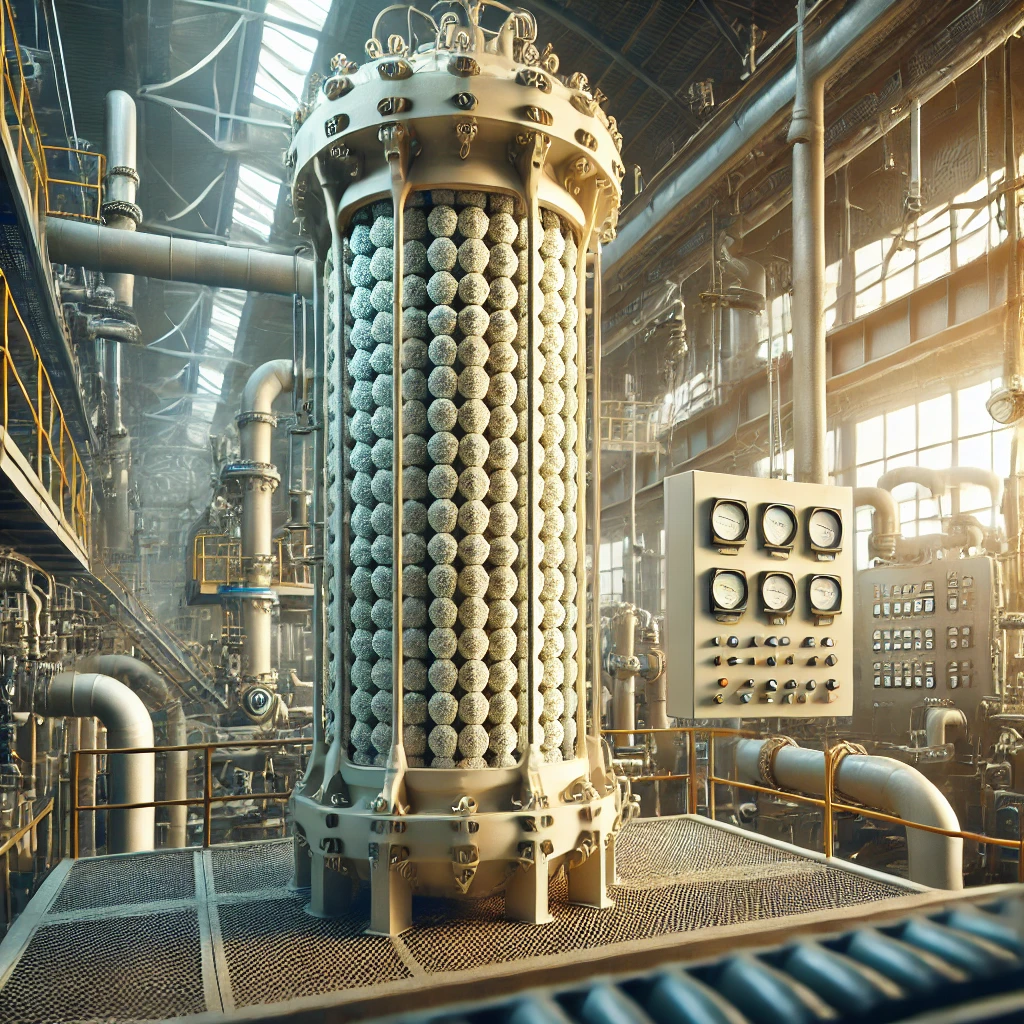

Rigid Zeolite / Ceramic Unit

This unit handles liquid phase tangential flow (TFF), pervaporation, and vapor permeation. Applications include solvent dehydration, water azeotrope breaking, metal removal, and other applications requiring robust and durable membrane materials. The unit is stainless steel and generally operates at pressures below 100 psi.

Low-Pressure Tangential Flow Unit

This stainless steel unit handles lower-pressure applications, evaluating sustained conditions for membranes in gentler environments, including biological separations.

Spiral Wound 2540 Unit

Designed for size 2540 membranes, this unit handles high and low-pressure reverse osmosis, nano-filtration, and ultra-filtration. It operates at pressures up to 1000 psi, accommodating testing of tote-size quantities.

Other Membrane Technology Equipment

Membrane technologies are just one of many process capabilities at Altiras Labs. We also have the following process research units to meet your testing needs:

- High-Speed CEPA centrifuge, designed for liquid-solid separations or liquid-liquid separations. This stainless steel unit is capable of 40,000 RPM

- Glass Atmospheric/Vacuum Distillation Unit – Made of borosilicate glass, this unit features a fixed tray design and operates with 5 to 30 physical trays, handling pressures from atmospheric down to 1 mbar.

- Wiped Film Evaporator Unit – Constructed with stainless steel and borosilicate glass, the primary 3” diameter unit excels in temperature-sensitive operations, reaching nearly 1 mbar pressure.

- RotoVap – This short-path borosilicate glass unit is ideal for short-path and high-solids testing.

- 1000 PSI Parr Pressure Reactor – A stainless steel unit used for various reactions including oxidation, hydrogenation, esterification, hydrolysis, and synthesis.

- Heaters and chillers – Pressure pumps and vacuum systems

- Vacuum ovens and incubators – Various analytical equipment including GC, automated Karl Fisher system, viscometers, flash point analyzers, colorimeters, densitometers, turbidity, pH, conductivity, sulfur analyzer, automated distillation range, muffle furnace, ultra-low temperature freezer, and much more

DRIVING INNOVATION WITH RIGOROUS RESEARCH

Altiras Labs is leading the application of membrane technologies for chemical recycling. Leveraging membrane technology with our expertise in traditional chemical processes, we develop solutions for the most challenging industrial residuals. Our process begins with a consult. This consultation enables us to develop a detailed roadmap, ensuring that our clients receive tailored solutions specific to their needs. Contact us today to see if we can help solve your recycling and reuse challenges.